Comparison of 3D nanofibrous structure and fabrication technique

| Technique/Structure | Pros | Cons | Suitable for |

| Vertical stacking of layers of fiber membrane

Each fiber layer may consist of non-woven fibers or aligned fibers.

|

Easy to mix different material Fixed and stable shape Easy to construct Conventional electrospinning setup Cell culture: Easy to seed cell on surface prior to stacking Able to construct scaffold with different layers and cell types |

Distinct interface is a source of mechanical weakness Not suitable for filling irregular shape cavities Proper treatment required to prevent layers from separating Very manual and time consuming Difficult to scale up Cell culture: Cells are unable to penetrate through layers |

Application where loading is compressive Barrier along the stacking axis is an advantage eg. filtration |

|

Layered yarns or beams

|

Controllable pore size between layers Fixed and stable shape Potential to scale up Cell culture: Interconnecting pores Large pore size |

Proper treatment required to maintain structure Not suitable for filling irregular shape cavities Modification of setup required Cell culture: Cell may fall through gap during seeding. |

Application where loading is compressive Tissue regeneration |

| Concentric fiber layer

|

Fixed and stable shape if bonding between yarns is adequate Conventional electrospinning setup Easy to construct Rolling of the concentrtic layer may be mechanized Cell culture: Easy to seed cell on surface prior to rolling Able to construct scaffold with different layers and cell types Easy for cells to migrate from end to end along longitudinal axis |

Proper treatment required to maintain shape Difficult to scale up Cell culture: Cells are unable to penetrate through the radial layers |

Barrier along the radial axis is required eg. filtration |

|

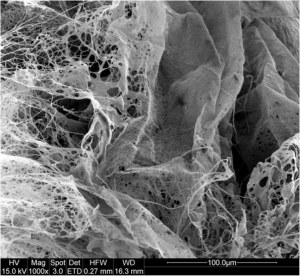

3D scaffold from thin layer membrane Consist of folds with two surfaces

See details |

Easy to construct Scaling up is possible |

Mechanically weak Uncontrollable pore size Unstable structure Custom setup required Cell culture: Non-uniform cell seeding density |

Application for filling irregular shape cavity

Tissue regeneration |

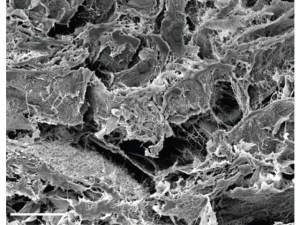

Fragments with binders See details |

Easy to construct Scaling up is possible Conventional setup Able to form defined shape with the use of binders Cell culture: Able to seed cell prior to forming 3D shape Interconnected pores |

Mechanically weak | Tissue regeneration where cell seeding prior to forming of 3D scaffold is desirable |

|

Progressive membrane buildup

Single, dense layer of fibers  See details

See details

|

Easy to construct Conventional setup |

Takes a long time to build up sufficiently thick layer

Cell culture: Limited cell penetration into its depth without membrane modification |

Affinity membrane with depth filtration |

|

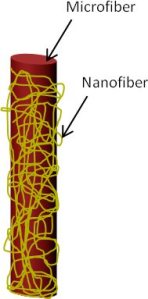

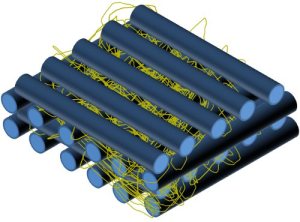

Nanofiber-microfiber combination a. Nanofiber coating on microfiber substrate

b. Nanofiber coating individual microfiber

See details |

a. Coating on microfiber substrate: Easy to construct Conventional setup Braiding or weaving of microfiber prior to coating Take advantage of superior strength of microfiber b. Coating on individual microfiber: Large pore size |

a. Coating on microfiber substrate: Clear distinction between nanofiber and microfiber layer b. Coating on individual microfiber: Modification of setup required Not suitable for application where defined shape is required |

Tissue regeneration a. Filtration membrane b. Affinity filter membrane |

Combining nanofibers with rapid prototyping (RP) technique

See details |

Take advantage of relative higher strength of RP structure Easy to build up 3D structure RP form able to maintain integrity |

Only suitable for RP technique that does not require support material Stable but limited forms |

Tissue regeneration |

Nanofiber with hydrogel

See details

See details

|

Take advantage of relative higher compressive strength of some hydrogel Easy to build up 3D structure Conventional electrospinning setup |

Difficult to get uniform fiber distribution in hydrogel | Tissue regeneration |

Particles leached nanofiber scaffold

See details

See details

|

Larger pore size than conventional setup Nanofibers only |

Slow to build up volume Mechanically weak |

Affinity filtration

Tissue regeneration |

Nanofiber structure from ice scaffolding

See details |

Larger pore size than conventional setup Nanofibers only |

Slow to build up volume Mechanically weak |

Tissue regeneration |

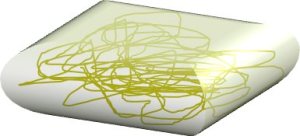

Nanofiber structure form on liquid surface

See details |

Larger pore size than conventional setup Nanofibers only |

Slow to build up volume Mechanically weak Generally require solvent reservoir as collector |

Tissue regeneration |

|

Sacrificial fibers

Non-woven membrane See details |

Larger pore size than conventional setup Nanofibers only |

Slow to build up volume Difficult to completely remove sacrificial fiber |

Tissue regeneration |

Self-bundling of nanofibers to form randomly organized nanofiber structure

See details |

Nanofibers only

Relative rapid buildup of nanofiber scaffold with volume |

Only possible for selective polymers or conditions

Structure lacks integrity |

Application where easily moldable scaffold is preferred.

Tissue regeneration |

Self-organized nanofibers See details |

Nanofibers only |

Only possible for selective polymers or conditions Structure lacks integrity Not possible to control fiber organization Slow process |

|

|

Electric field charges Randomly organized 3D nanofiber structure See details |

Nanofibers only Relative rapid buildup of nanofiber scaffold with volume |

Structure lacks integrity Modification of setup required |

Application where easily moldable scaffold is preferred |

|

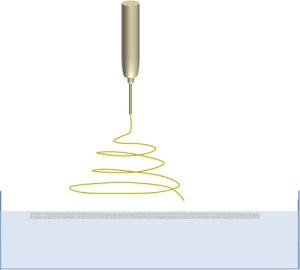

Water vortex Randomly organized nanofibrous yarns  See details |

Nanofibers only Relative rapid buildup of nanofiber scaffold with volume Large inter-yarn pore size Yarn microstructure |

Structure lacks integrity Modification of setup required Freeze-drying to remove water |

Application where easily moldable scaffold is preferred Tissue regeneration |

Lamellar flow – Single nanofiber layer membrane forming 3D nanofibrous structure

See details |

Nanofibers only Relative rapid buildup of nanofiber scaffold with volume |

Structure lacks integrity Modification of setup required Freeze-drying to remove water |

Application where easily moldable scaffold is preferred Tissue regeneration |

|

3D nanofibrous structure using waterflow Randomly organized nanofibers See details |

Nanofibers only Relative rapid buildup of nanofiber scaffold with volume |

Structure lacks integrity Modification of setup required Freeze-drying to remove water |

|

|

Ultrasonic vibration Randomly organized nanofibers See details |

Nanofibers only Conventional setup |

Structure lacks integrity Freeze-drying to remove water |

|

|

Mechanical combing to unravel nanofiber from membrane Randomly organized nanofibers See details |

Nanofibers only Conventional setup Simple |

Compromised structure due to damaged nanofiber Not practical to scale up Structure lacks integrity |

Published date: 14 April 2013

Last updated: -

Last updated: -

Comments

ElectrospinTech

ElectrospinTech