▼ Reference

- Anderson K D, Lu D, McConney M E, Han T, Reneker D H, Tsukruk V V. Hydrogel microstructures combined with electrospun fibers and photopatterning for shape and modulus control. Polymer 2008; 49: 5284.

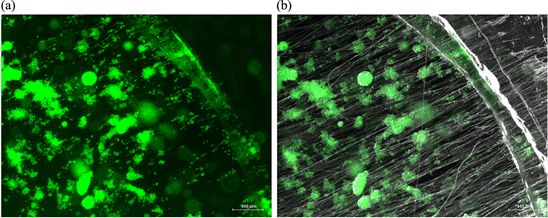

- Ekaputra A K, Prestwich G D, Cool S M, Hutmacher D W (2008) Combining Electrospun Scaffolds with Electrosprayed Hydrogels Leads to Three-Dimensional Cellularization of Hybrid Constructs. Biomacromolecules 9 pp. 2097-2103

- Eslami M, Vrana N E, Zorlutuna P, Sant S, Jung S, Masoumi N, Khavari-Nejad R A, Javadi G, Khademhosseini A. Fiber-reinforced hydrogel scaffolds for heart valve tissue engineering. Journal of Biomaterials Applications 2014 Ahead of print. DOI: 10.1177/0885328214530589.

- Formica F A, Ozturk E, Hess S C, Stark W J, Maniura-Weber K, Rottmar M, Zenobi-Wong M. A Bioinspired Ultraporous Nanofiber-Hydrogel Mimic of the Cartilage Extracellular Matrix. Advanced Healthcare Materials 2016; 5: 3129. Ghafari A M,Rajabi-Zeleti S, Naji M, Ghanian M H, Baharvand H. Mechanical reinforcement of urinary bladder matrix by electrospun polycaprolactone nanobers. Scientia Iranica F 2017; 24: 3476. Open Access

- Kai D, Prabhakaran M P, Stahl B, Eblenkamp M, Wintermantel E, Ramakrishna S. Mechanical properties and in vitro behavior of nanofiber-hydrogel composites for tissue engineering applications. Nanotechnology 2012; 23: 095705.

- Keller L, Wagner Q, Pugliano M, Breda P, Ehlinger M, Schwinte P, Benkirane-Jessel N. Bi-layered Nano Active Implant with Hybrid Stem Cell Microtissues for Tuned Cartilage Hypertrophy. Journal of Stem Cell Research & Therapeutics 2015; 1: 0004. Open Access

- Kong B, Sun W, Chen G, Tang S, Li M, Shao Z, Mi S. Tissue-engineered cornea constructed with compressed collagen and laser-perforated electrospun mat. Scientific Reports 2017; 7: 970. Open Access

- Kosowska K, Domalik-Pyzik P, Krok-Borkowicz M, Chlopek J. Polylactide/Hydroxyapatite Nonwovens Incorporated into Chitosan/Graphene Materials Hydrogels to Form Novel Hierarchical Scaffolds. Int J Mol Sci. 2020 Apr; 21(7): 2330. Open Access

- Liu W, Zhan J, Su Y, Wu T, Ramakrishna S, Liao S, Mo X. Injectable hydrogel incorporating with nanoyarn for bone regeneration. Journal of Biomaterials Science, Polymer Edition 2014; 25: 168.

- Liu X, Gao L, Fu S, Zhao W, Wang F, Gao J, Li C, Wu H, Wang L. Polycaprolactone nanofiber-alginate hydrogel interpenetrated skin substitute for regulation of wound-substitute interface. Materials & Design 2023; 227: 111706. Open Access

- Matera D L, DiLillo K M, Smith M R, Davidson C D, Parikh R, Said M, Wilke C A, Lombaert I M, Arnold K B, Moore B B, Baker B M. Microengineered 3D pulmonary interstitial mimetics highlight a critical role for matrix degradation in myofibroblast differentiation. Science Advances 2020; 6: eabb5069. Open Access

- McMurtrey R J. Patterned and functionalized nanofiber scaffolds in three-dimensional hydrogel constructs enhance neurite outgrowth and directional control. J Neural Eng 2014; 11: 066009. Open Access

- Pan J F, Liu N H, Sun H, Xu F. Preparation and Characterization of Electrospun PLCL/Poloxamer Nanofibers and Dextran/Gelatin Hydrogels for Skin Tissue Engineering. PLoS ONE 2014; 9(11): e112885. Open Access

- Rivet C J, Zhou K, Gilbert R J, Finkelstein D I, Forsythe J S. Cell infiltration into a 3D electrospun fiber and hydrogel hybrid scaffold implanted in the brain. Biomatter 2015; 5: e1005527. Open Access

- Sakai S, Takagi Y, Yamada Y, Yamaguchi T and Kawakami K (2008) Reinforcement of porous alginate scaffolds by incorporating electrospun fibres. Biomed. Mater. 3 034102 (6pp)

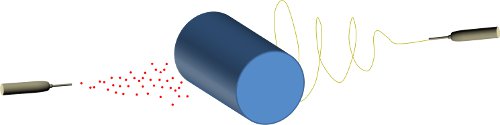

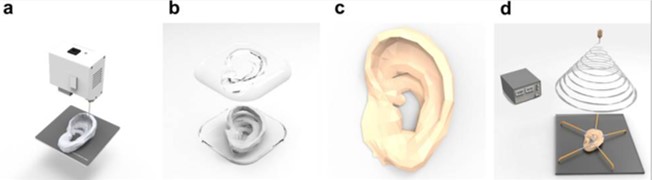

- Song J Y, Ryu H I, Lee J M, Bae S H, Lee J W, Yi C C, Park S M. Conformal Fabrication of an Electrospun Nanofiber Mat on a 3D Ear Cartilage-Shaped Hydrogel Collector Based on Hydrogel-Assisted Electrospinning. Nanoscale Res Lett. 2021 Jul 9;16(1):116. Open Access

- Visser J, Melchels F P W, Jeon J E, Bussel E M, Kimpton L S, Byrne H M, Dhert W J A, Dalton P D, Hutmacher D W, Malda J. Reinforcement of hydrogels using three-dimensionally printed microfibres. Nature Communications 2015; 6: 6933.

- Xu T, Binder K W, Albanna M Z, Dice D, Zhao W, Yoo J J, Atala A. Hybrid printing of mechanically and biologically improved constructs for cartilage tissue engineering applications. Biofabrication 2013;5: 015001.

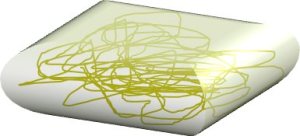

- Yang Y, Wimpenny I. Ahearne M (2011) Portable nanofiber meshes dictate cell orientation throughout three-dimensional hydrogels. Nanomedicine: Nanotechnology, Biology and Medicine 7, pp. 131-136

- Yao S, Yu S, Cao Z, Yang Y, Yu X, Mao H Q, Wang L N, Sun X, Zhao L, Wang X. Hierarchically aligned fibrin nanofiber hydrogel accelerated axonal regrowth and locomotor function recovery in rat spinal cord injury. International Journal of Nanomedicine 2018:13 2883. Open Access

▼ Credit and Acknowledgement

Author

Wee-Eong TEO View profile

Email: weeeong@yahoo.com

ElectrospinTech

ElectrospinTech