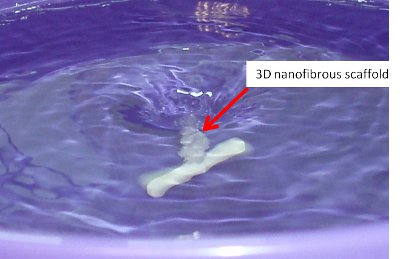

3D nanofiber using water flow

|

| Gathering of nanofiber clump around the rotating stirring bar |

The fluid nature of water makes it a unique substrate for the collection and modification of nanofibers during the electrospinning process. By controlling the movement of water, different nanofibrous structures can be constructed. The low "adhesion" between the nanofibers and water also allows movement of the nanofibers without breaking them (under reasonable flow).

One method of constructing a 3D nanofibrous structure is to create a vortex using a spinning rotor. A long magnetic stirring bar may be made to rotate in a basin of water using a magnetic stirrer. As nanofibers are deposited on the surface of the water, the vortex drags the deposited fibers towards the rotating bar and causes it to spin around itself. The bundling of the nanofibers within the water vortex results in the formation of a clump of nanofibers.

A static low surface tension collector liquid often results in the accumulation of the fibers just below its surface. Although the resultant scaffold is less compact than those collected on a solid surface, the pore size may still be quite small and may still have a flat profile. To encourage better dispersion of the fibers along the depth of the reservoir, the liquid may be agitated such that the fibers do not settle on the surface. Since the liquid has a low surface tension, the setup does not require a strong water flow to sink the fibers. Xu et al (2018) used an ethanol bath for collection of electrospun polyacrylonitrile (PAN) fibers. However, instead of constant agitation during fiber collection, the electrospun fibers were allowed to collect for 5 minutes in the ethanol bath before it was shaken to disperse the fibers. With this they were able to successfully construct 3D scaffold after freeze drying.

Last updated: 15 May 2018

ElectrospinTech

ElectrospinTech