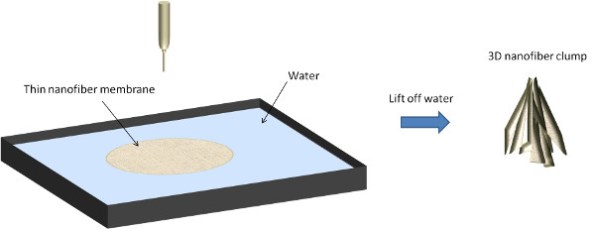

Thin layer 3D membrane

3D nanofibrous scaffold made of thin nanofiber membrane. |

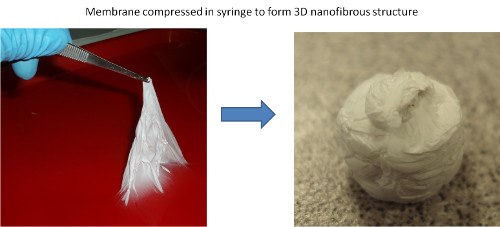

3D nanofiber scaffold made out of compressed nonwoven membrane |

- Easy to make

- Large production is possible with multiple spinnerets

Disadvantages:

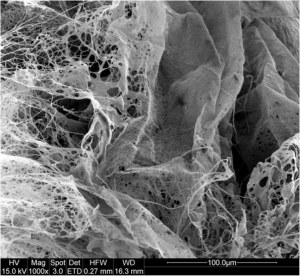

- 3D structure is made out of folds and are not interconnected

- Spinneret must be above the water (free-surface electrospinning is not possible)

In a stagnant pool of water, fibers will accumulate on the water surface with larger thickness at the center. The volume of the scaffold obtained from a thin nanofibrous membrane deposited over a small surface area will be very small. To increase the volume, the fiber needs to be deposited over a larger surface area. One way to achieve this is to have a slow flowing water surface. As the fiber accumulates on the water surface, it gets transported away as more fiber continuously gathers behind. The fibers may be transported to a holding area where it is can be accumulated.

A nanofibrous membrane, if sufficiently thin, can be easily compressed to form a nanofibrous clump. The challenge is to separate the thin membrane from the collector. Using water as a collector, this can be easily accomplished. Electrospinning may be carried out over a reservoir of water and the nanofiber membrane will float on the surface of the water. The membrane may then be lifted off the surface of the water and compressed to form a clump of nanofibers. The wet nanofibrous clump may be dried under room condition or freeze-dried.

In some cases, it may be necessary to incorporate binding agent (eg. fibrin glue, gelatin) when compressing the membrane so that the 3D structure does not unravel during tissue culture. However, if the membrane is sufficiently thin, it is unlikely that the compressed structure will unravel.

|

| Photo illustration |

Last updated: 30 March 2013

ElectrospinTech

ElectrospinTech