Mimicking cortical bone architecture

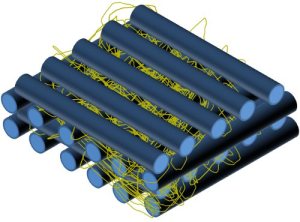

The cortical bone is made out of hollow cylindrical structures called the osteon. There are numerous researches into the development of cortical regenerative scaffold as it may not be feasible to harvest autologous cortical bone. Linder et al (2020) used a modified parallel electrodes collector electrospinning method to wrap highly aligned polycaprolactone (PCL) polymer nanofibers around individual 1393 bioactive glass microfibers to mimic the structure of osteon. The setup was made of two rotatable round plates and a stationary holder in the center of the plates to insert the glass microfiber between the plates. During electrospinning, fibers would deposit on the edges of the round plates. Rotation of the plates in opposing directions wraps the fibers around the center glass microfiber. Having electrospun fibers wrapped around the glass microfiber ensures that the scaffold remains intact even if the bioglass breaks. In vitro study showed the polymer wrapping did not inhibit the degradation of the bioglass for conversion into calcium phosphate. Further the aligned PCL fibers were shown to facilitate cell migration and elongation along the length of the scaffold. With this electrospinning setup, other biocompatible rods or cylinders may be coated with aligned nanofibers. The versatility of this process will see more innovative ways to enhance bone treatment

To mimic the structure of a cortical bone, Kim and Lee (2011) went into great extent to construct a scaffold consisting of several nanofibrous sub-components and a ceramic sponge replica. In general, the middle of the cylindrical scaffold is a cylindrical ZrO2/biphasic calcium phosphate sponge replica. Surrounding it were nanofibrous rods with longitudinal holes that runs the full length of the rod.

Since electrospun 3D nanofibers are known to be soft, an obvious advantage of this construct will be the compressive strength derived from the inner ceramic sponge. The compressive strength of the assembly was found to be 4.97 MPa and the porosity is 70%. Osteoblast-like MG-63 was cultured on the specimen and was found to be 90% viable after 3 days using MTT assay. Despite the excellent physical conformance to native cortical bone, there are several other considerations that needed further investigation. The pore size of the nanofiber membrane surrouding each sub-component may limit the migration of cells through the walls and its impact on in vivo mineralization. It remains to be seen whether cells are able to take advantage of the longitudinal holes within the scaffold for migration or the hole may collapsed when soaked in blood. Given the scaffold is made out numerous sub-components, natural fault-lines will be present between each sub-component and it is vital that these does not cause separation of the sub-components in vivo.

Yun et al (2019) electrospun a poly(lactide-co-glycolide)/hydroxyapatite nanofibres sheet and roll into a thick wall cylinder with wall thickness of 2 mm. A 3D melt printing method was used to replicate the radius bone segment of the study subject, beagle dog. The 3D printed poly(lactic-acid) (PLA) scaffold has a hollow in the center which was filled in with the rolled poly(lactide-co-glycolide)/hydroxyapatite nanofibres prior to implantation into the segmental bone defect. The 3D printed PLA scaffold provided the mechanical support to maintain the shape of the assembly while the electrospun nanofibres layer is able to provide the surface topography for better cell adhesion and proliferation. During implantation, gelatine was added along with the scaffold assembly to function as glue and to promote cell adhesion. However, the scaffold assembly alone is unable to promote bone generation. Only in the group with rhBMP-2 and gelatine added during implantation showed significant bone regeneration.

One way of increasing the compressive strength and ensure greater integration between layers within scaffold is through mineralization. The mineralization process will deposit minerals on exposed surfaces and interfaces within the scaffold which reduces the probability of delamination between layers. Heat treatment may also be carried out post-mineralization to enhance fusion between deposited minerals and the polymer fibers. Adric et al (2014) created a bone scaffold by first constructing small diameter nanofibrous tube before wrapping with nanofiber membrane which is similar to stage 2 and stage 3 of the above mentioned process. However, the nanofiber coating that surrounds the small diameter tubes are formed by rolling over the tubes with electrospun membrane instead of direct coating. Mineralization and heat treatment was carried out on the whole scaffold and the resultant scaffold showed a compressive yield stress of about 600 kPa which demonstrated the difficulty of getting electrospun scaffold with high compressive strength.

Electrospinning and Freeze drying

To create a 3D block structure, Kim et al combined electrospin fibers with freeze drying of collagen. Bioactive glass nanofiber was first fabricated by electrospinning of bioactive glass sol-poly-vinyl-butyral mixture followed by sintering to remove the organic component. The resultant bioactive glass nanofiber membrane is mixed with collagen solution followed by freeze-drying. ALP expression of osteoblast on the collagen/ bioactive glass nanofiber composite was significantly greater than collagen alone at 7 days [Kim et al 2006].

Microfiber and nanofiber hybrid structure

Electrospinning was used in combination with rapid prototyping scaffold (3D plotting technique) to generate a 3D porous frame with electrospun nanofibers membrane between two successive layers of plotted microfibers (Read more). Osteoblastic-like cells isolated from human osteosarcoma-derived cells exhibited greater ALP expression at day 7 when seeded on the rapid prototyped scaffold with electrospun nanofibers than on rapid prototyped scaffold without the nanofibers [Martins et al 2009]. Another method to combine microfibers and nanofibers is to electrospin nanofibers on non-woven microfibers (wet spinning). The resultant hybrid mesh can be stacked as layers to give it greater depth [Tuzlakoglu et al 2011]. In the construction of microfiber/nanofiber hybrid structure, electrospinning alone may be used to construct the hybrid structure by altering the material used or the material's concentration. Kwon et al (2017) created a hybrid structure of poly(lactide-co-glycolide) (PLGA) microfiber and collagen-hydroxyapatite composite nanofibers. PLGA microfiber was first electrospun and subsequently coated with dopamine before electrospinning collagen nanofibers containing L-glutamic acid-grafted hydroxyapatite nanorods (nHA-GA). The polydopamine coating on the surface of PLGA microfiber induces covalent bonding on the collagen nanofibers. MTT assay for studying MC3T3E1 showed that PLGA with dopamine and HA showed significantly more cell viability compared to PLGA only, PLGA with dopamine and PLGA-HA.

Mineralized yarn 3D scaffold

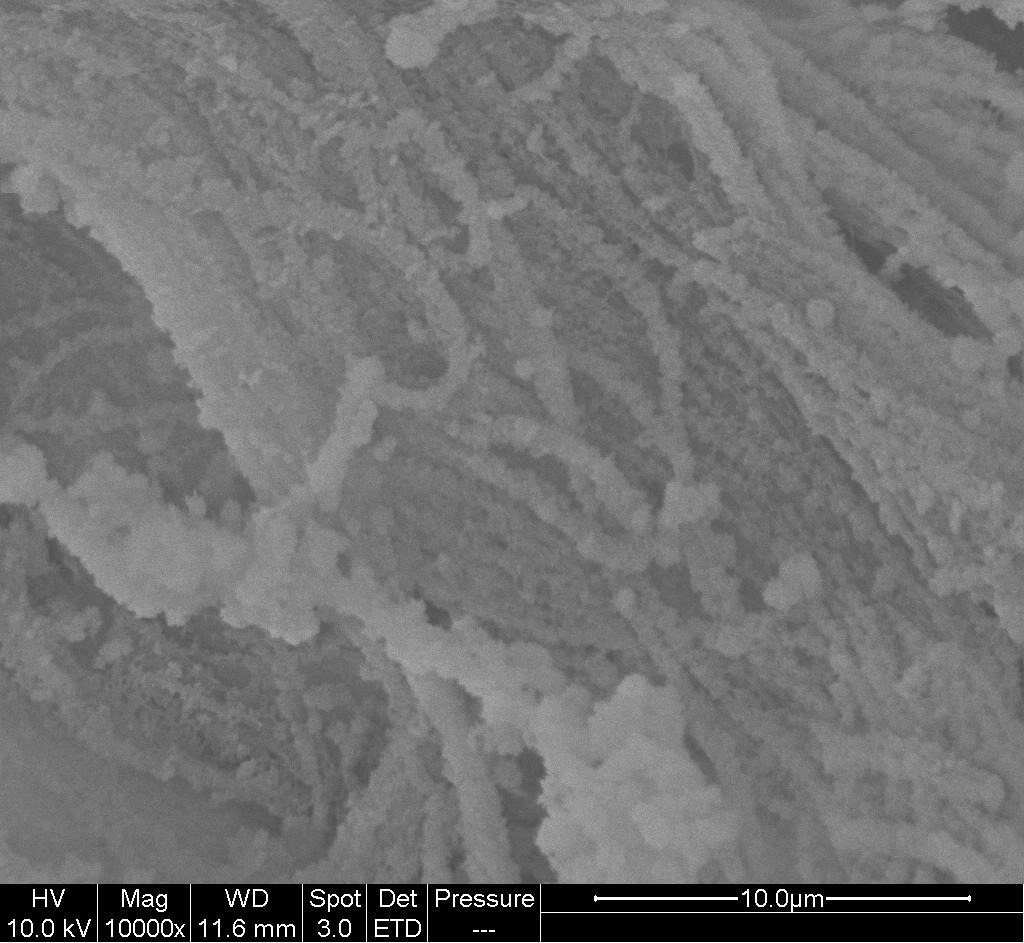

Using the dynamic flow method, Teo et al was able to construct a 3D nanofibrous scaffold that is made out of yarn microstructure [Teo 2009, Teo et al 2007]. Alternate soaking mineralization (Calcium salt and phosphate salt solution) method was used to deposit nHA onto the yarn microstructure followed by freeze drying. Teo et al showed that by alternate flow of the two parts solution through the scaffold, nHa was able to form in the core of the scaffold instead of on the surface only [Teo 2009, Teo et al 2011]. Ngiam used a similar technique to form the mineralized scaffold. However, instead of carrying out the mineralization in a cylindrical mold, she carried out the mineralization in alternate solution reservoir before freeze drying in a mold [Ngiam 2010].

Tubular/Cylindrical structure

The tubular structure was constructed by rolling a PCL/collagen sheet pre-seeded on both sides with mesenchymal cells on a pipette followed by an outer most layer of osteogenic cell sheet. After culturing in osteogenic medium for 2 months, the compressive stiffness and modulus along the axial direction of the structure (0.86 N/mm and 2.4 MPa respectively) with cell sheet was much greater than that without cells sheet [Ekaputra et al 2009].

Wang et al used a salt-leaching method was combined with electrospinning to form a spiral form cylindrical scaffold [Wang et al 2010]. In brief, a PCL polymer sheet was first formed by drying a salt-filled PCL solution before electrospinning was carried out on both sides of the sheet to deposit a layer of PCL nanofibers. The resultant hybrid polymer sheet was rolled along with a piece of copper sheet and incubated at 45 degrees Celsius before submerging in cold water to set the shape. After the copper sheet is removed, the resultant spiral form cylindrical scaffold was submerged in de-ionized water to remove the salt particles. Human osteoblast cells cultured on spiral form cylindrical scaffold with and without the nanofiber coating, and full volume porous cylindrical scaffold (phase inversion and salt leaching method) showed highest alkaline phosphatase activity, cell numbers and calcium amount in the spiral form cylindrical scaffold with nanofibers and the least for full volume cylindrical scaffold. The compressive modulus and yield strength was found to be 1.56 MPa and 0.42 MPa respectively.

Kosowska et al (2020) used an electrospun polylactide/hydroxyapatite (PLA/HA) fiber membrane and chitosan/graphene (CS/GO) hydrogel in the construction of a hierarchically organized bone scaffold. Electrospinning was first carried out using a blend of PLA and HA to form a fibrous membrane. A CS/GO suspension was spread over the membrane before rolling into a cylinder. The construct was frozen before immersing in gelling solution to form the final scaffold. The steps of coating the membrane and freezing the construct is important to maintain a gap between the overlapping membrane. This gap meant that cells will be able to infiltrate into the depth of the scaffold.

Published date: 05 November 2012

Last updated: 16 November 2021

▼ Reference

-

Andric T, Taylor B L, Degen K E, Whittington A R, Freeman J W. Fabrication and Characterization of Three Dimensional Electrospun Cortical Bone Scaffolds. Nanomat. Environ. 2014; 2: 13.

Open Access

-

Ekaputra A K, Zhou Y, Cool S M, Hutmacher D W. Composite Electrospun Scaffolds for Engineering Tubular Bone Grafts. Tissue Engineering 2009; 15: 3779.

-

Kim H W, Song J H, Kim H E. Bioactive glass nanofiber-collagen nanocomposite as a novel bone regeneration matrix. J Biomed Mater. Res. 2006; 79A: 698.

-

Kim Y H, Lee B T (2011) Novel approach to the fabrication of an artificial small bone using a combination of sponge replica and electrospinning methods. Sci. Technol. Adv. Mater. 12, 035002 (7pp).

Open Access

-

Kosowska K, Domalik-Pyzik P, Krok-Borkowicz M, Chlopek J. Polylactide/Hydroxyapatite Nonwovens Incorporated into Chitosan/Graphene Materials Hydrogels to Form Novel Hierarchical Scaffolds. Int J Mol Sci. 2020 Apr; 21(7): 2330.

Open Access

-

Kwon G W, Gupta K C, Jung K H, Kang I K. Lamination of microfibrous PLGA fabric by electrospinning a layer of collagen-hydroxyapatite composite nanofibers for bone tissue engineering. Biomaterials Research 2017; 21: 11.

Open Access

-

Linder H R, Glass A A, Day D E, Sell s A. Manipulating Air-Gap Electrospinning to Create Aligned Polymer Nanofiber-Wrapped Glass Microfibers for Cortical Bone Tissue Engineering. Bioengineering 2020; 7(4): 165

Open Access

-

Ngiam L M. Differentiation of bone marrow derived mesenchymal stem cells (BM-MSCs) using engineered nanofiber substrates. PhD Thesis NUS 2011.

Open Access

-

Teo W E, Gopal R, Ramaseshan R, Fujihara K, Ramakrishna S. A dynamic liquid support system for continuous electrospun yarn fabrication. Polymer 2007; 48: 3400.

-

Teo W E, Liao S, Chan C, Ramakrishna S. Fabrication and characterization of hierarchically organized nanoparticle-reinforced nanofibrous composite scaffolds. Acta. Biomater. 2011; 7: 193.

-

Teo W E. Natured Inspired Composite Nanofibers. Masters Thesis, NUS 2009.

Open Access

-

Tuzlakoglu K, Santos M I, Neves N, Reis R L. Design of Nano- and Microfiber Combined Scaffolds by Electrospinning of Collagen onto Starch-Based Fiber Meshes: A Man-Made Equivalent of Natural Extracellular Matrix. Tissue Engineering Part A 2011; 17: 463.

-

Wang J, Valmikinathan C M, Liu W, Laurencin C T, Yu X. Spiral-structured, nanofibrous, 3D scaffolds for bone tissue engineering. J. Biomed. Mater. Res. 2010; 93A: 753.

-

Yun J W, Heo S Y, Lee M H, Lee H B. Evaluation of a poly(lactic-acid) scaffold filled with poly(lactide-co-glycolide)/hydroxyapatite nanofibres for reconstruction of a segmental bone defect in a canine model. Veterinarni Medicina 2019; 64: 531.

Open Access

▲ Close list

ElectrospinTech

ElectrospinTech AutoCAD images of (a) the final design of the modified air-gap electrospinning with motor setup, signifying the stationary (green) and rotating (black) parts. (b) A simplified setup demonstrating the wrapping of electrospun fibers (blue) around the glass fiber (red) [Linder et al 2020]

AutoCAD images of (a) the final design of the modified air-gap electrospinning with motor setup, signifying the stationary (green) and rotating (black) parts. (b) A simplified setup demonstrating the wrapping of electrospun fibers (blue) around the glass fiber (red) [Linder et al 2020]