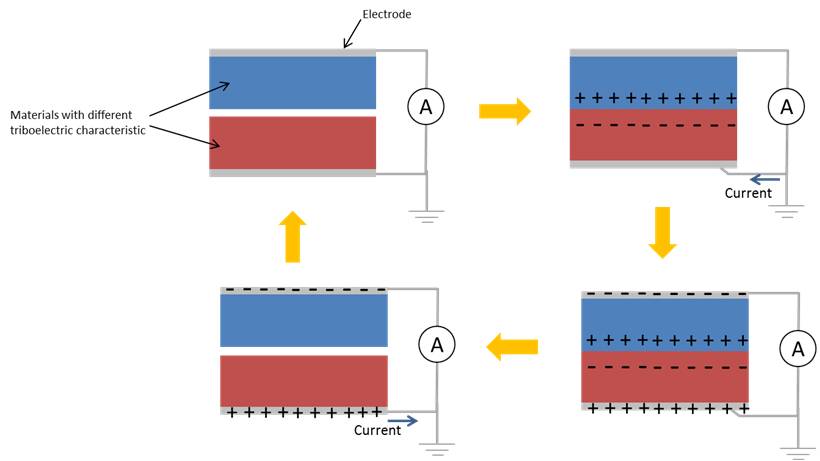

Triboelectric power generation is the harvesting of charges induced from triboelectric processes to convert mechanical energy into electric power. The basic production of triboelectric charges involves having two materials with distinctly different triboelectric characteristics to induce equal but opposite charges on them when there is friction. When the conductive electrode is placed at the back of each material, an electric current would flow to the electrode to achieve electrostatic equilibrium with the corresponding charged material. When the two materials are not in contact, the induced charges on the materials may neutralize and the electric charges on the electrodes would flow in the opposite direction to achieve electrostatic equilibrium. Since the first publication of using tribelectric charges to power electronic devices by Fan et al (2012), this concept have been tested using electrospun membrane. White et al (2023) used an electrospun Polyvinylidene Fluoride (PVDF) fibre loaded with Polytetrafluoroethylene (PTFE) for the construction of a triboelectric power generator. PVDF is a high-performance piezoelectric polymer with negative triboelectric properties and PTFE is one of the most negative triboelectric materials. The voltage output from cyclical compressive force on electrospun fibers loaded with 4wt% PTFE was 5 times greater than 100% PVDF electrospun fibers. The highest output voltage from the PTFE/PVDF fibers was about 55 V at 12 Hz. Having nylon fabric in the assembly as a triboelectric donor material resulted in a further 80% increase in output voltage.

The amount of induced triboelectric charges have a direct influence on the overall power generation. While selecting materials that are far apart along the triboelectric series would contribute to it, another factor is the surface roughness. This is where electrospun nanofibers have an advantage. High surface area of electrospun nanofibers increases the surface contact area and the amount of triboelectric charges generated. Ye et al (2015) selected poly(vinylidene fluoride-cohexafluoropropylene) (P(VDF-HFP)) and Kapton for the construction of a triboelectric nanogenerator device. Comparing the performance of spin coated poly(vinylidene fluoride-cohexafluoropropylene) (P(VDF-HFP)) and electrospun P(VDF-HFP) nanofiber membrane, they found that the power output of the electrospun membrane was higher at 20 V and 19 µAcm-2 to 3 V and 5 µAcm-2 of spin coated P(VDF-HFP). By doping ionic liquid 1-ethyl-3-methylimidazolium bis(trifluoromethylsufonyl)imide, [EMIM][TFSI] into P(VDF-HFP), they were able to fabricate ion gel nanofibers and further improve the output of the triboelectric nanogenerator device to 45 V and 49 µAcm-2.

Yang et al (2024) selected sodium bismuth titanate (Na½Bi½TiO3, NBT) and barium zirconate titanate (BaZrxTi1-xO3, BZT) as additives for electrospun ethylcellulose (EC) nanofibers membrane. NBT has a high Curie Temperature (TC = 320 °C), large inverse piezoelectric coefficient and large field-induced strain while BZT is a lead-free relaxor ferroelectric material with a high piezoelectric constant and large dielectric constant. NBT-BZT nanoparticles were synthesized by the solid-state method before being blended into EC for electrospinning. To ensure a smooth electrospinning process, a coaxial spinneret was used with the EC/NBT-10BZT solution flowing through the core and ethanol through the outer nozzle. The EC/NBT-10BZT composite film formed the positive triboelectric layer and fluorinated ethylene propylene (FEP) film as the negative triboelectric layer. The constructed TENG gave a maximum output current of 4 µA, and a maximum output power density of 134 µW/cm2.

The amount of triboelectric charges generated is also influenced by environmental conditions such as humidity and dust. To improve the robustness of the triboelectric nanogenerator such that it can be used in different conditions, Gu et al (2015) constructed an enclosed triboelectric nanogenerator with electrospun PVDF fibrous membrane and polyethylene (PE) film to generate negative triboelectric charges in a 4-parts setup. A PVC plate covered with a layer of Al was sandwiched between the PVDF fibrous membrane and PE film. Charges are induced when sound wave caused the PVDF fibrous membrane and PE film to vibrate and rub against the Al layer. This setup was able to generate a maximum output voltage of 72 V and current of 0.66 mA when sound waves passed through it, sufficient to light up 24 red commercial LEDs without energy storage. The sealed setup was tested in high humidity with no change in its power generation but unsealed setup showed a drop in current by 65.4% at relative humidity of 100% compared with that at relative humidity of 15%.

Having both contacting surfaces made out of electrospun membrane have the potential to improve the electrical charges output. Zheng et al (2014) fabricated a triboelectric nanogenerator with one surface made of electrospun PVDF and the other, electrospun Nylon. With this setup, they were able to generate a peak power density of 26.6 Wm-2. Comparing the output of electrospun surfaces with smooth surfaces, the former generated a current of 81 µA while the latter generated a current of only 19 µA. This provides further evidence of the advantage of electrospun membrane in triboelectric power generation.

There are several factors that influence the output of a triboelectric power generation. Higher dielectric value of the material such as PVDF may improve the power output but this is not always the case. Zhou (2024) constructed a TENG with thermoplastic polyurethane (TPU)/PVDF as the negative triboelectric material and nylon as the positive triboelectric materials. In the electrospun blend of PVDF/thermoplastic polyurethane (TPU), the maximum electrical output of the TENG was when the PVDF in the PVDF/TPU film was at 15%. Lower strength of PVDF may have caused a reduction in charge transfer efficiency during contact separation. The optimum thickness of the PVDF/TPU film in terms of electrical output was found to be 50 µm with Voc of 195.17 V, an Isc of 18.41 µm and Qsc of 46.09 nC. At greater thickness, the electrical output of the TENG dropped. Larger separation distance was also found to generate greater electrical output. A maximum output voltage of 699 µW was recorded for the TENG.

With ordered electrospun fibers, the triboelectric generation of assembled devices can be improved. Linarts et al (2023) constructed layer-by-layer triboelectric laminate structures from sequential electrospinning of ordered large and small polymer fibers.The larger diameter electrospun aligned Ethylene vinyl acetate (EVA) fibers has a diameter of a few microns while the smaller diameter electrospun aligned polylactic acid (PLA) fibers has a diameter of a few hundred nanometers. When the smaller diameter PLA fibers were the base, the larger diameter EVA fibers were able to slip over the smaller diameter PLA fibers. However, when the larger diameter EVA fibers form the base, subsequent layers of PLA fibers tend to sit between the EVA fibers which locks both surfaces in place. By having a laminate with sequenctial layers of EVA and PLA, this resulted in slippery interface layers for energy generation and fixed interface layers. With this the Tests on the electrical output showed that the sequentially electrospun laminate membrane has an output of 0.75 nA while layers with the same polymer fiber facing each other showed negligible output of 0.04 nA. Interestingly, individual layers of membrane stacked on one another showed an intermediate output of 0.11 nA. Therefore, the close arrangement of the fibers in sequentially electrospun laminate membrane was able to generate a higher output which goes beyond material properties.

Charge storage and output potential of electrospun fibers may be improved by having additives blended into the fibers. Huang et al (2015) demonstrated this by dispersing graphene oxide (GO) in PVDF nanofibers. Using PVDF/GO and poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) nanofibers as contacting surfaces, they found that the maximum output voltage and current was 340 V and 78 µA respectively when GO concentration was 0.7%. This is an increase of 78.9% and 188.9% over pure PVDF fibers. Their study also found that reduction of PVDF fiber diameter also improves the voltage generated by 28.9% (from 190 to 245V) when the diameter was reduced from 650 nm to 250 nm.

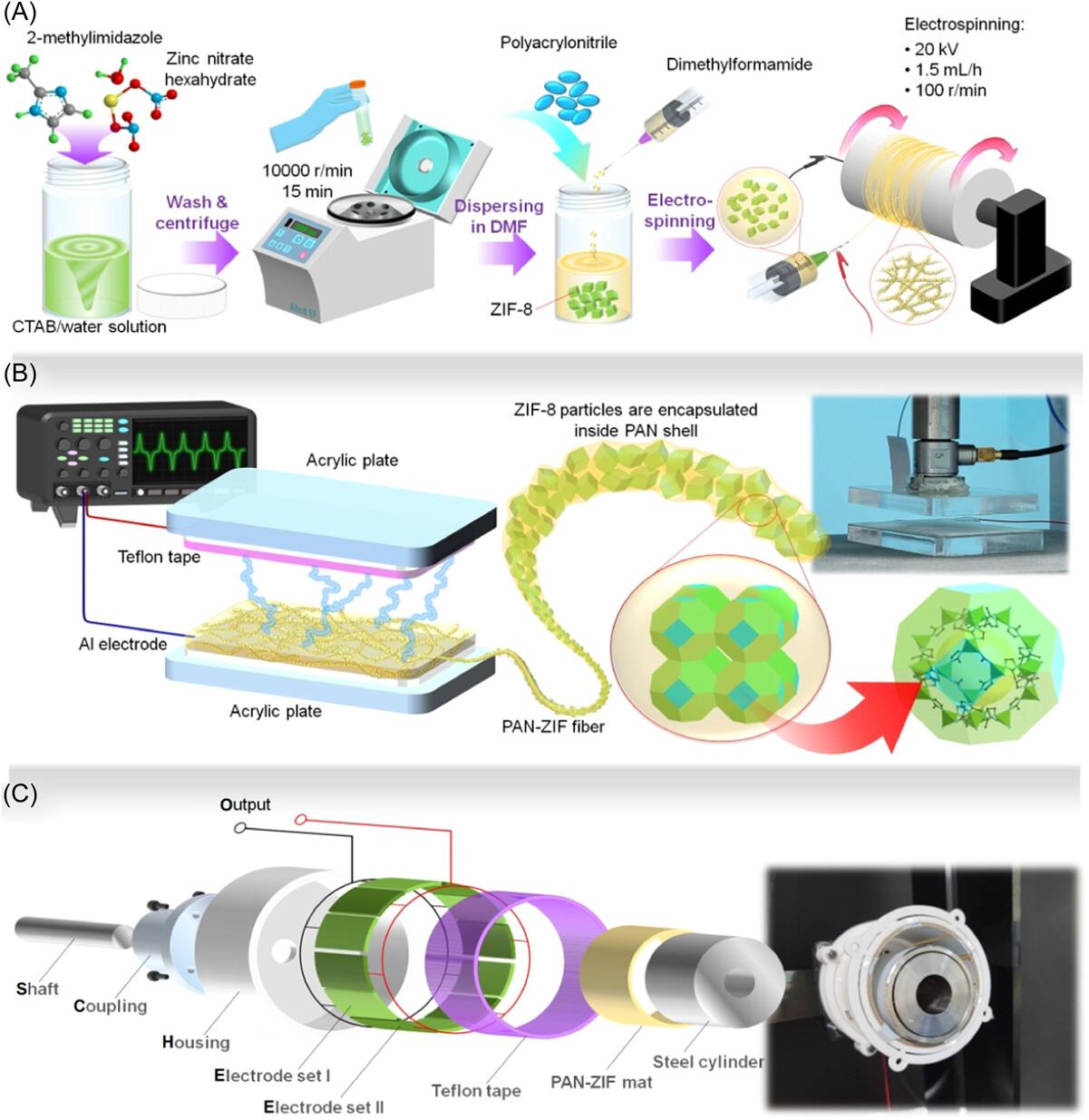

Tabassian et al (2024) blended a metal-organic framework, zeolitic imidazolate framework (ZIF-8) into polyacrylonitrile (PAN) solution to electrospin ZIF/PAN nanofibrous mat. ZIF-8 nanocrystals have high surface potential, good temperature stability and are resistant to environmental degradation. The resultant electrospun ZIF/PAN nanofibers had a rough surface due to the cubic ZIF nanocrystals which increased triboelectrification. The voltage output of triboelectric nanogenerator (TENG) with ZIF/PAN nanofibrous mat at optimum ZIF loading of 1.5 wt% was 178 V and current of 7.5 µA which is significantly greater than pure PAN electrospun nanofibrous mat with voltage output of 100 V and current of 4.1 µA. The higher output can be attributed to the enhanced surface charges of the ZIF/PAN nanofibers due to ZIF. Greater surface roughness which increases the effective contact area would also increase the output. Greater addition of ZIF may cause aggregation of the nanoparticles and cause uneven distribution. A maximum power density of 204.8 mW/m2 was obtained with a 100 MOhm resistor. For the TENG assembly, instead of the conventional system of contact/separation or sliding modes, Tabassian et al (2024) introduced a rolling mechanism which is expected to have less mechanical stress on the component due to its smoother and continuous motion.

The relative ease of generating power using this setup has encouraged its incorporation into devices. Zheng et al (2014) were able to directly power a DC motor and a UV radiation detection device with their triboelectric nanogenerator. Quan et al (2015) used a combination of triboelectric nanogenerator and electromagnetic electric generator to power an electronic watch. The triboelectric nanogenerator was found to deliver a maximum power output of 0.1 mW while the electromagnetic electric generator was able to deliver a maximum power output of 6.1 mW. The combined electrical output can be stored in a Li-ion battery to increase the usage duration of the watch to 218 min from 32 min of charging.

Peng et al (2020) constructed a self-powered electronic skin using electrospun triboelectric nanogenerators. This triboelectric nanogenerator is made out of electrospun polylactic-co-glycolic acid (PLGA) fibers layer and an electrospun polyvinyl alcohol (PVA) fibers layer with silver nanowires (AgNW) sandwiched between the two layers. To have this AgNW layer, a vacuum filtration method was used to pass a suspension of AgNW solution through the electrospun PVA membrane layer where the nanofibers membrane traps the AgNW. Electrospinning of PLGA was carried out with the electrospun PVA membrane loaded with AgNW as the collector. A copper foil was attached to the surface of the membrane as the lead out. Electricity generation and transmission is realized by the periodic contact and separation between the constructed electronic skin (e-skin) and a contact object. The induced potential difference between the inner AgNW inner electrode and the external ground object will cause a charge transfer between them and generates a current. A maximum areal power density of 130 mW m-2 at a matched resistance of ~500 megohms was recorded for the PLGA/Ag NWs/PVA e-skin.

To supplement and regenerate static electricity on the facemask, triboelectric nanogenerator (TENG) which uses friction to generate electrostatic charges may be employed. Kang et al (2023) constructed a fluffy membrane layer containing electrospun polytetrafluoroethylene (PTFE)/polyvinyl alcohol (PVA) and polyvinylidene fluoride fibers

(HENM) using two separate nozzles but simultaneously deposited on a rotating collector wrapped with polypropylene (PP) melt-blown cloth. The PTFE/PVA fibers were electrospun through blending of PTFE emulsions and PVA solution. Static electricity was generated by friction between the electrospun membrane and the PP melt-blown cloth. The static electricity generated was able to compensate for the charge loss during the breathing process. The initial filtration efficiency of as-spun PTFE/PVA-PVDF fibers ranged from 40% to 70%. After 4 rounds of filtration, the filtration efficiency increased sharply to more than 95% and gradually towards 100%. The increase in filtration efficiency has been attributed to triboelectric charging due to friction collision occurred between particles and fiber, instead of cake formation

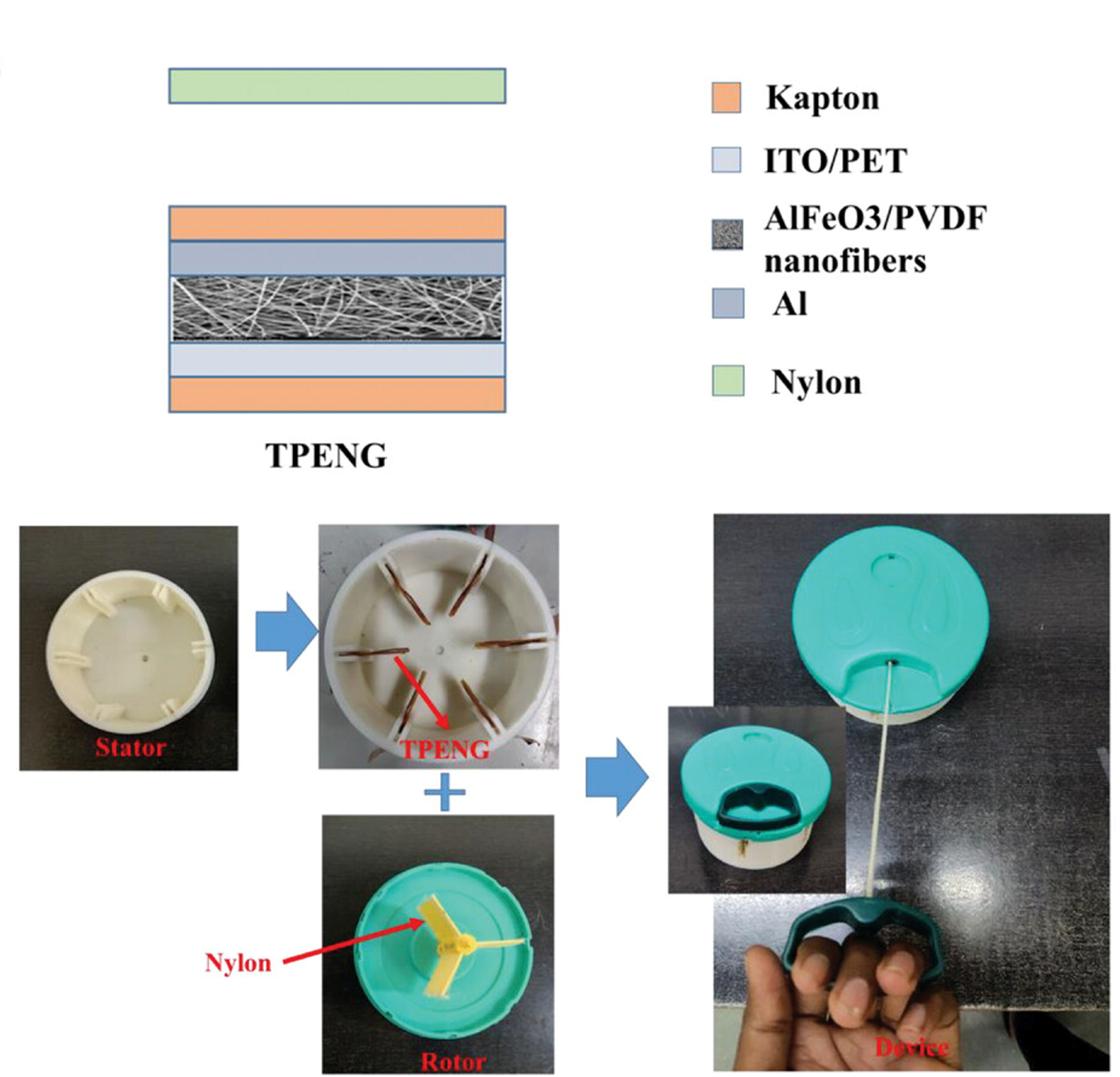

While a triboelectric nanogenerator uses friction to generate power, a piezoelectric nanogenerator uses mechanical stress on piezoelectric material to generate power. With the right assembly, it is possible to construct a power generator that utilizes both triboelectric and piezoelectric effects. Das et al (2024) constructed a tribo-enhanced piezoelectric nanogenerator (TPENG) comprised of AlFeO3/PVDF nanofibers with two asymmetric electrodes (Al and ITO/PET). The assembly is in the form of a stator and a moving rotor. The PENG device was made of electrospun AlFeO3/PVDF nanofibers sandwiched between an Al sheet base and an ITO/PET sheet and the three layers wrapped with Kapton tape which acts as a tribo-negative material. For the nanogenerator, the PENG assembly formed the stator. Nylon fabric which acts as the tribo-positive material to create friction was used to wrap the fin of the rotor. Hence the rotor rubbing the stator generates charges similar to a TENG and the periodic bending of the stator generates charges similar to a PENG. Each TPENG was able to produce an output of Voc and Isc at 52.3 V and 1.23 µA, respectively. With six TPENGs in a circular arrangement, the device was able to generate a Voc of 200 V and an Isc of 4.5 µA.

Published date: 03 May 2016

Last updated: 15 July 2025

▼ Reference

-

Das N K, Badhulika S. Flexible Tribo-Enhanced Piezoelectric Nanogenerator Based on Aluminium Ferrite Electrospun Hybrid Nanofibers for Energy Harvesting and Patient Rehabilitation Application. Advanced Sensor Research 2024; 3: 2400023.

https://onlinelibrary.wiley.com/doi/10.1002/adsr.202400023 Open Access

-

Fan F R, Tian Z Q, Wang Z L. Flexible triboelectric generator. Nano Energy 2012; 1: 328.

-

Gu L, Cui N, Liu J, Zheng Y, Bai S, Qin Y. Packaged triboelectric nanogenerator with high endurability for severe environments. Nanoscale 2015; 7: 18049.

-

Huang T, Lu M, Yu H, Zhang Q, Wang H, Zhu M. Enhanced Power Output of a Triboelectric Nanogenerator Composed of Electrospun Nanofiber Mats Doped with Graphene Oxide. Nature Scientific Reports 2015; 5: 13942.

Open Access

-

Kang L, Ma C, Wang J. Gao X, An G. PTFE/PVA-PVDF Conjugated Electrospun Nanofiber Membrane with Triboelectric Effect Used in Face Mask. Fibers Polym 2023; 24: 1975.

Open Access

-

Linarts A, Sherrell P C, Malnieks K, Ellis A V, Sutka A. Electrospinning Triboelectric Laminates: A Pathway for Scaling Energy Harvesters. Small 2023; 19: 2205563.

Open Access

-

Peng X, Dong K, Ye C, Jiang Y, Zhai S, Cheng R, Liu D, Gao X, Wang J, Wang Z L. A breathable, biodegradable, antibacterial, and self-powered electronic skin based on all-nanofiber triboelectric nanogenerators. Science Advances 2020; 6: eaba9624.

Open Access

-

Quan T, Wang X, Wang Z L, Yang Y. Hybridized Electromagnetic-Triboelectric Nanogenerator for a Self-Powered Electronic Watch. ACS Nano 2015; 9: 12301.

-

Tabassian R, Rajabi-Abhari A, Mahato M, Yoo H, Yoon H Y, Park J Y, Oh I K. Metal-organic framework-based nanofibrous film for two different modes of triboelectric nanogenerators. Smart Mat 2024; e1270

Open Access

-

White P, Bavykin D, Moshrefi-Torbati M, Beeby S. The Energy Harvesting Performance of a Flexible Triboelectric-Based Electrospun PTFE/PVDF Fibre. Engineering Proceedings. 2023; 30(1):8.

Open Access

-

Ye B U, Kim B J, Ryu J, Lee J Y, Baik J M, Hong K. Electrospun ion gel nanofibers for flexible triboelectric nanogenerator: electrochemical effect on output power. Nanoscale 2015; 7: 16189.

-

Zheng Y, Cheng L, Yuan M, Wang Z, Zhang L, Qin Y, Jing T. An electrospun nanowire-based triboelectric nanogenerator and its application in a fully selfpowered UV detector. Nanoscale 2014; 6: 7842.

-

Zhou H. A triboelectric nanogenerator based on TPU/PVDF electrospinning for mechanical energy harvesting and monitoring running step rate. AIP Advances 2024; 14 (6): 065229.

https://pubs.aip.org/aip/adv/article/14/6/065229/3299033 Open Access

▲ Close list

ElectrospinTech

ElectrospinTech