▼ Reference

- Ekaputra A K, Prestwich G D, Cool S M, Hutmacher D W (2008) Combining Electrospun Scaffolds with Electrosprayed Hydrogels Leads to Three-Dimensional Cellularization of Hybrid Constructs. Biomacromolecules 9 pp. 2097-2103.

- Kai D, Prabhakaran M P, Stahl B, Eblenkamp M, Wintermantel E, Ramakrishna S. Mechanical properties and in vitro behavior of nanofiber-hydrogel composites for tissue engineering applications. Nanotechnology 2012; 23: 095705.

- Liu W, Zhan J, Su Y, Wu T, Ramakrishna S, Liao S, Mo X. Injectable hydrogel incorporating with nanoyarn for bone regeneration. Journal of Biomaterials Science, Polymer Edition 2014; 25: 168.

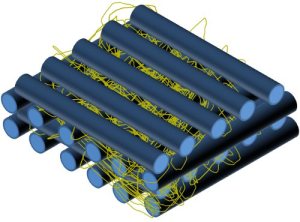

- Visser J, Melchels F P W, Jeon J E, Bussel E M, Kimpton L S, Byrne H M, Dhert W J A, Dalton P D, Hutmacher D W, Malda J. Reinforcement of hydrogels using three-dimensionally printed microfibres. Nature Communications 2015; 6: 6933. Open Access

- Yang Y, Wimpenny I. Ahearne M (2011) Portable nanofiber meshes dictate cell orientation throughout three-dimensional hydrogels. Nanomedicine: Nanotechnology, Biology and Medicine 7, pp. 131-136

- Zhou Y, Hu Z, Du D, Tan G Z. The effects of collector geometry on the internal structure of the 3D nanofiber scaffold fabricated by divergent electrospinning. The International Journal of Advanced Manufacturing Technology 2018 Article in press.

▼ Credit and Acknowledgement

Author

Wee-Eong TEO View profile

Email: weeeong@yahoo.com

ElectrospinTech

ElectrospinTech