There are many applications which require protein adsorption on electrospun fibers. In tissue engineering and regenerative scaffold, protein adsorption on the fiber surface encourages cell adhesion and proliferation. In biochips and biosensors, adsorption may be used to immobilize proteins for proper functioning.

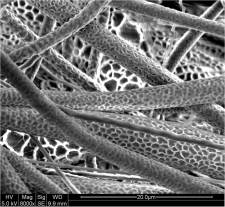

Greater surface area of nanofiber for protein adsorption has been recommended for better cell adhesion and proliferation performance [Leong et al 2009]. Nanofibers with roughened or porous surface has been shown to adsorb 80% more proteins than smooth surface nanofiber scaffold after 24 h [Leong et al 2009].

High surface area of electrospun nanofibers made it very attractive for sensor application. Depending on the intended purpose of the protein, it is sometimes necessary to ensure that the adsorbed proteins are fixed on the fibers and does not leach during usage. Liu et al (2010) found that the addition of LiCl in electrospun polymeric fibers significantly increases adsorption of proteins such as bovine serum albumin (BSA) and protamine, with over 64% (w/w) of the dry mass of fibers. Further, these proteins remain firmly attached to the fibers despite washing vigorously with fresh buffer solutions. This allowed them to use the proteins for covalent attachment of an outer layer of an enzyme, α-chymotrypsin and the enzyme retains its activity after being incubated for 8 months at 4 °C in aqueous buffer solution.

A bonding agent may be applied on the electrospun fiber surface for better adhesion with the protein. Zhao et al (2019) tested the use of polydopamine (PDA) as a bonding agent on electrospun poly(lactic-co-glycolic acid) (PLGA) fibers for surface adhesion of fibroblast growth factor (bFGF) and ponericin G1. PDA is a molecule found in the adhesive proteins of mussel and can improve hydrophilicity and functionalize the surface coated with it. Zhao et al (2019) applied PDA on electrospun PLGA fibers by dipping the fibers in PDA solution for a few hours, rinsing in deionized water and drying. The resultant PLGA/PDA fibers were loaded with bFGF and ponericin G1 by dipping in respective solution, rinsing in distilled water and drying. Loading of bFGF on pure PLGA scaffold was about 38% but the addition of PDA on the PLGA fibers increases the loading efficiency to 76%.

Immobilization of glucose oxidase may be achieved by electrostatic interaction between negative charges in the enzyme with a positively charged material. Manesh et al (2008) used positively charged multi-walled carbon nanotube (MWCNT) wrapped in a cationic polymer (poly(diallyldimethylammonium chloride) (PDDA)) to immobilize glucose oxidase on the surface of polymethylmethacrylate (PMMA) nanofiber. The process involved electrospinning a blend of MWCNT/PDDA/PMMA onto an ITO-coated glass plate and incubating the assembly in glucose oxidase solution. To improve selectivity against interfering species such as ascorbic acid and uric acid, a thin layer of nafion was coated. Negatively charged nafion is able to electrostatically repel negatively charged ascorbic acid and uric acid [Manesh et al 2008]

In most applications it is vital that the immobilized protein is able to maintain its activity for its intended purpose. Morita et al (2017) showed that the diameter of polyurethane fibers affect the activity of adsorbed protein. Using model protein, horseradish peroxidase (HRP), with thicker fibers (diameter 950 nm), there is a decrease in activity due to large conformational changes. However, on smaller diameter fibers (diameter 480 nm), the protein was able to retain a close-to-natural shape which translate to higher activity. Their study showed that the amount of HRP adsorbed were independent of fiber diameter therefore the reduction of activity was not due to amount of adsorbed HRP. Investigating the secondary structure of adsorbed HRP on the fibers showed significantly less α-helix and β-helix percentages on the HRP adsorbed on thicker fibers compared to natural state HRP. However, the percentage of α-helix and β-helix on smaller diameter fibers were similar to natural state HRP indicating almost no structural change in the protein.

Published date: 06 Feb 2018

Last updated: 03 March 2020

▼ Reference

-

Leong M F, Chian K S, Mhaisalkar P S, Ong W F, Ratner B D. Effect of electrospun poly(D,L-lactide) fibrous scaffold with nanoporous surface on attachment of porcine esophageal epithelial cells and protein adsorption. J Biomed Mater Res 2009; 89A: 1040.

-

Liu C X, Zhang S P, Su Z G, Wang P. Salt Induced Irreversible Protein Adsorption with Extremely High Loadings on Electrospun Nanofibers. Langmuir 2010; 27: 760

-

Manesh K M, Kim H T, Santhosh P, Gopalan A I, Lee K P. A novel glucose biosensor based on immobilization of glucose oxidase into multiwall carbon nanotubes-polyelectrolyte-loaded electrospun nanofibrous membrane. Biosensors and Bioelectronics 2008; 23: 771

-

Morita Y, Sakamoto H, Suye S I. Characterization of protein adsorption on stretched polyurethane nanofibers prepared by electrospinning. RSC Adv.; 2017: 7 56484.

Open Access

-

Zhao J, Han F, Zhang W, Yang Y, You D, Li L. Toward improved wound dressings: effects of polydopamine-decorated poly(lactic-co-glycolic acid) electrospinning incorporating basic fibroblast growth factor and ponericin G1. RSC Adv. 2019; 9: 33038.

Open Access

▲ Close list

ElectrospinTech

ElectrospinTech