Layered Fibers Folds

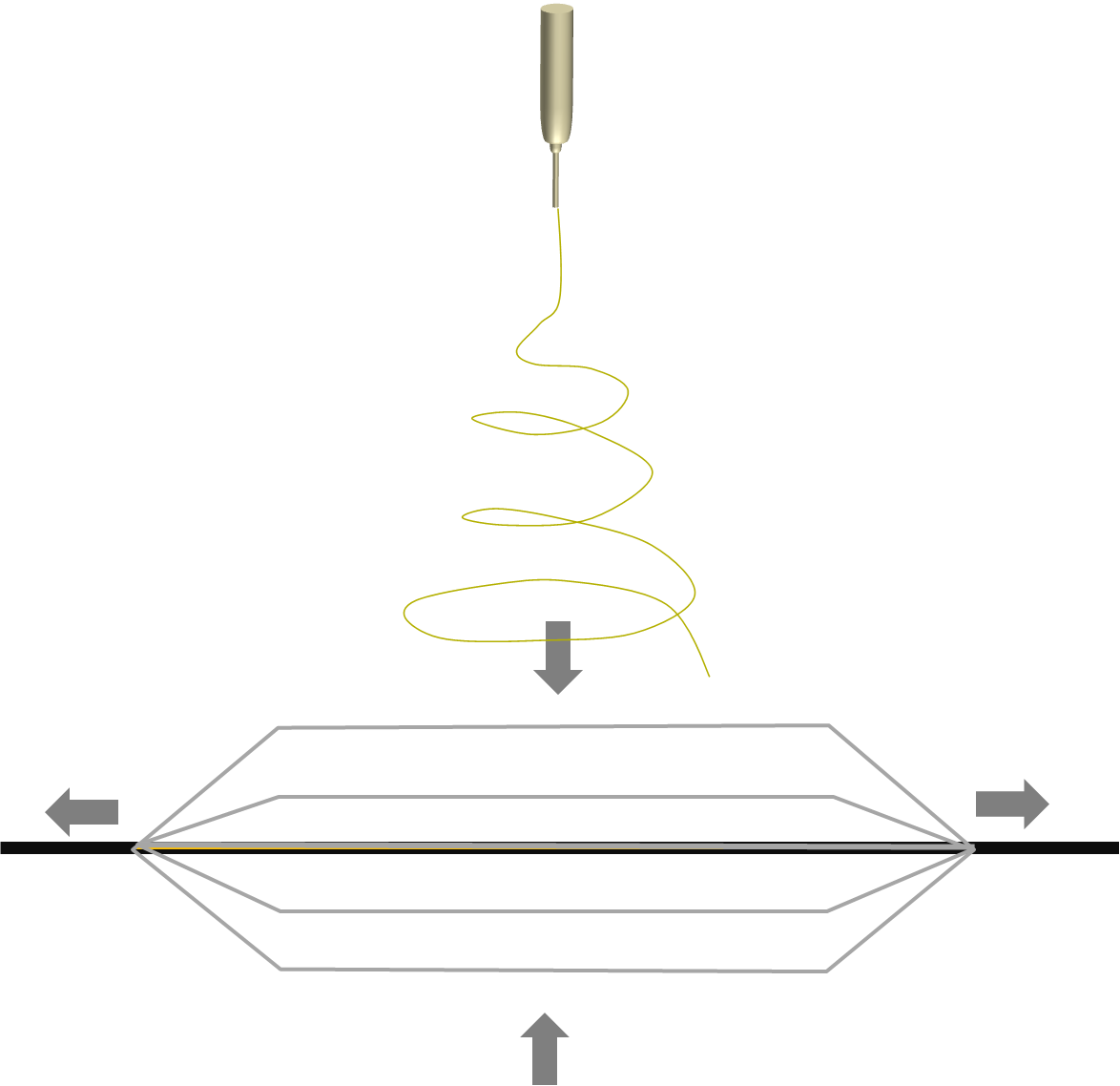

Figure 1. Rotating frame collector with collapsable struts |

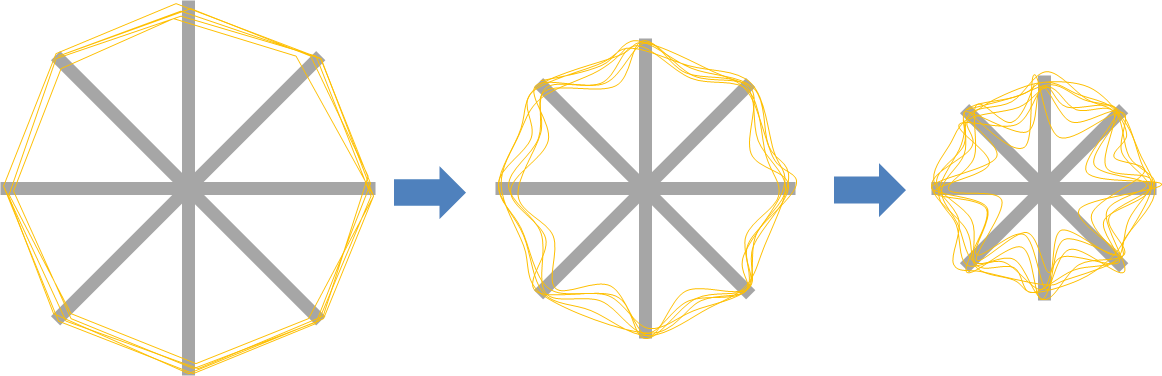

Figure 2. Side view of the parallel struts setup showing the fibers deposited across the gap between the struts. As the struts are withdrawn towards the axial rod, the deposited fibers are folded inwards while more fibers aligned across the gap. |

The apparent low mechanical strength of individual nanofibers means that construction of 3D block nanofibers during the electrospinning process by mechanical method has not been developed until now. Although the nanofiber is unable to take on load, its flexibility allows it to bend easily and this concept has been used successfully to construct 3D block nanofibers during the electrospinning process. In the design by Ru et al [2013], the mechanical collector has parallel struts that can be brought towards the axial rod as the end appendages fold as shown in figure 1.

During electrospinning, the frame collector is rotated so that fibers can be deposited across all the parallel struts. Concurrently, the struts are withdrawn towards the axial rod resulting in the folding of the earlier deposited fibers as subsequent fibers are deposited across the struts as shown in figure 2. The resultant 3D scaffold will be made out of layers of fibrous folds. By controlling the rate of parallel struts withdrawal, the porosity of the scaffold may be varied. .

Last updated: -

ElectrospinTech

ElectrospinTech