▼ Reference

- Abdel-Hady, Alzahrany A, Hamed M. Experimental Validation of Upward Electrospinning Process. ISRN Nanotechnology 2011; 2011: 851317.

- Amiraliyan N, Nouri M, Kish M H. Effects of Some Electrospinning Parameters on Morphology of Natural Silk-Based Nanofibers. J Appl Polym Sci 2009; 113: 226.

- Wang X W, Cao J, Hu Z M, Pan W L, Liu Z F. Jet Shaping Nanofibers and the Collection of Nanofiber Mats in Electrospinning. J. Mater. Sci. Technol. 2006; 22: 536. Open Access

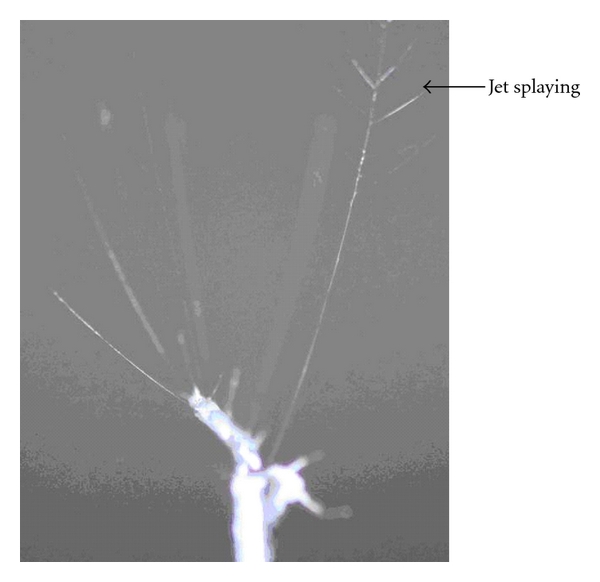

- Yarin A L, Kataphinan W, Reneker D H. Branching in electrospinning of nanofibers. Journal of Applied Physics 2005; 98: 064501.

- Zhao S L, Wu X H, Wang L G, Huang Y. Electrospinning of Ethyl-Cyanoethyl Cellulose/Tetrahydrofuran Solutions. J. Appl. Polym. Sci. 2004; 91: 242.

▼ Credit and Acknowledgement

Author

Wee-Eong TEO View profile

Email: weeeong@yahoo.com

ElectrospinTech

ElectrospinTech