▼ Reference

- Abolhasani M M, Azimi S, Mousavi M, Anwar S, Amiri M H, Shirvanimoghaddam K, Naebe M, Michels J, Asadi K. Porous graphene/poly(vinylidene fluoride) nanofibers for pressure sensing. Journal of Applied Polymer Science 2022; 139: 51907. Open Access

- Ahn Y, Lim J Y L, Hong S M, Lee J, Ha J, Choi H J, Seo Y. Enhanced Piezoelectric Properties of Electrospun Poly(vinylidene fluoride)/Multiwalled Carbon Nanotube Composites Due to High β-Phase Formation in Poly(vinylidene fluoride). The Journal of Physical Chemistry C 2013; 117: 11791.

- Costa L M M, Bretas R E S, Gregorio Jr. R. Effect of Solution Concentration on the Electrospray/Electrospinning Transition and on the Crystalline Phase of PVDF. Materials Sciences and Applications 2010; 1: 247. Open Access

- Cozza E S, Monticelli O, Marsano E, Cebe P. On the electrospinning of PVDF: influence of the experimental conditions on the nanofiber properties. Polymer International 2013; 62: 41.

- He Z, Rault F, Vishwakarma A, Mohsenzadeh E, Salaün F. High-Aligned PVDF Nanofibers with a High Electroactive Phase Prepared by Systematically Optimizing the Solution Property and Process Parameters of Electrospinning. Coatings. 2022; 12(9):1310. Open Access

- Huang F, Wei Q, Wang J, Cai Y, Huang Y. Effect of temperature on structure, morphology and crystallinity of PVDF nanofibers via electrospinning. e-Polymers 2008; 152. Open Access

- Kang S B, Won S H, Im M J, Kim C U, Park W I, Baik J M, Choi K J. Enhanced piezoresponse of highly aligned electrospun poly(vinylidene fluoride) nanofibers. Nanotechnology 2017; 28: 395402.

- Lei T, Yu L, Zheng G, Wang L, Wu D, Sun D. Electrospinning-induced preferred dipole orientation in PVDF fibers. Journal of Materials Science 2015; 50: 4342.

- Li B,i Xu C, Zheng J, Xu C. Sensitivity of Pressure Sensors Enhanced by Doping Silver Nanowires. Sensors 2014; 14: 9889.

- Lin Y, Yao Y Y, Yang X Z, Shen L M, Li R X, Wu D C. Effect of gas flow rate on crystal structures of electrospun and gas-jet/electrospun poly(vinylidene fluoride) fibers. Chinese Journal of Polymer Science 2009; 27: 511.

- Parker A, Ueda A, Marvinney CE, Hargrove SK, Williams F, Mu R. Structural and Thermal Treatment Evaluation of Electrospun PVDF Nanofibers for Sensors. J Polym Sci Appl 2018; 2:1. Open Access

- Prasad G, Liang J W, Zhao W, Yao Y B, Tao T, Liang B, Lu S G. Enhancement of solvent uptake in porous PVDF nanofibers derived by a water-mediated electrospinning technique. Journal of Materiomics 2020 Article in press. Open Access

- Sengupta D, Kottapalli A G P, Chen S H, Miao J M, Kwok C Y, Triantafyllou M S, Warkiani M E, Asadnia M. Characterization of single polyvinylidene fluoride (PVDF) nanofiber for flow sensing applications. AIP Advances 2017; 7: 105205. Open Access

- Sengupta D, Michael A, Kwok C Y, Miao J, Kottapalli A G P. Optimized Polyvinylidene Fluoride Nanofiber Webs for Flexible Energy Harvesters. Proceedings 2018; 2: 857. Open Access

- Silva M P, Costa C M, Sencadas V, Paleo A J, Lanceros-Méndez S. Degradation of the dielectric and piezoelectric response of β -poly(vinylidene fluoride) after temperature annealing. Journal of Polymer Research 2011; 18: 1451.

- Song H, Song W, Song J H, Torrejon V M, Xia Q. Electrospun 1D and 2D Carbon and Polyvinylidene Fluoride (PVDF) Piezoelectric Nanocomposites. Journal of Nanomaterials 2022; 2022: 9452318. Open Access

- Yin J-Y, Boaretti C, Lorenzetti A, Martucci A, Roso M, Modesti M. Effects of Solvent and Electrospinning Parameters on the Morphology and Piezoelectric Properties of PVDF Nanofibrous Membrane. Nanomaterials. 2022; 12(6):962. Open Access

- Yoon K, Kelarakis A. Nanoclay-Directed Structure and Morphology in PVDF Electrospun Membranes. Journal of Nanomaterials 2014; 2014: 367671. Open Access

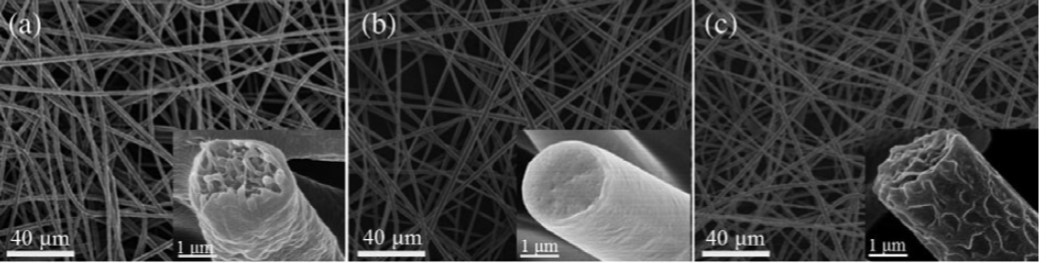

- Zaarour B, Zhu L, Huang C, Jin X. Fabrication of a polyvinylidene fluoride cactus-like nanofiber through one-step electrospinning. RSC Adv., 2018, 8, 42353. Open Access

- Zaarour B, Zhu L, Huang C, Jin X. Enhanced piezoelectric properties of randomly oriented and aligned electrospun PVDF fibers by regulating the surface morphology. J. Appl. Polym. Sci. 2019; 136: 47049.

▼ Credit and Acknowledgement

Author

Wee-Eong TEO View profile

Email: weeeong@yahoo.com

ElectrospinTech

ElectrospinTech