Air blown 3D nanofibrous structure

|

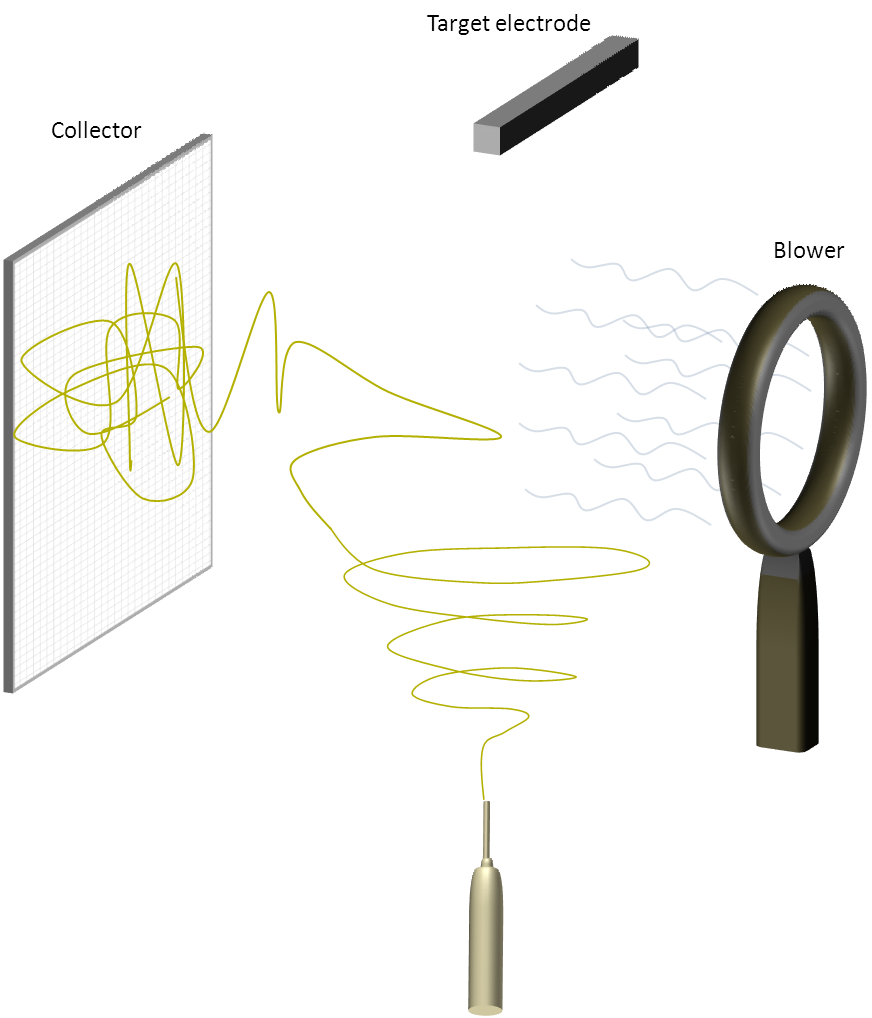

| Using blowing air to redirect electrospinning jet to obtain a 3D clump of nanofibrous scaffold. |

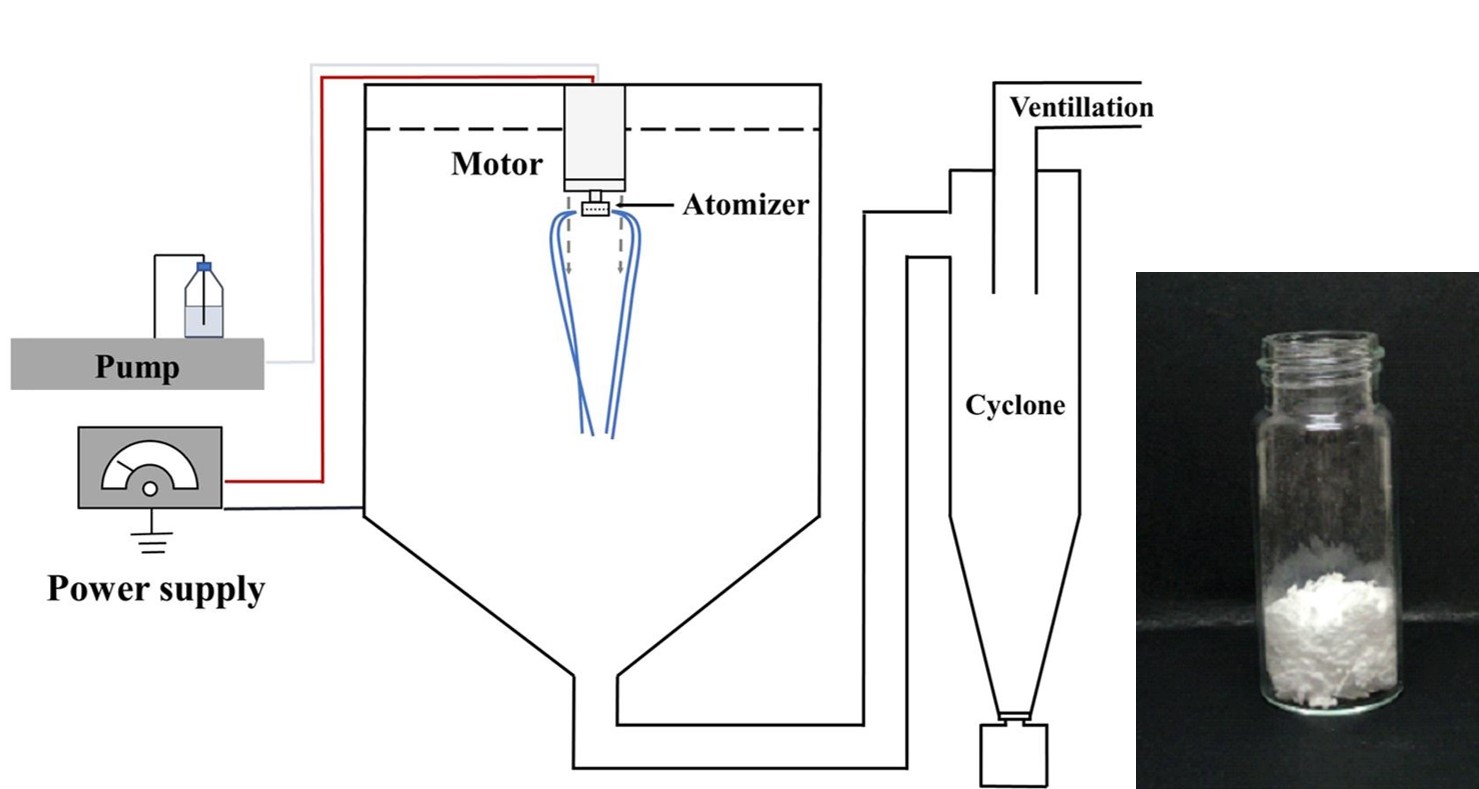

Light weight nature of nanofibers makes them susceptible to displacement by air circulation. During electrospinning, light air circulation does not have a significant impact on fiber deposition due to the electrostatic attraction exerted by the collector on the charged jet. However, a strong wind may be able to overcome the electrostatic attraction and redirect the jet path to an alternative collector. The strong wind movement may also reduce the charges on the electrospinning jet such that deposition on the alternate collector is based on general adhesion instead of electrostatic attraction. Without the electrostatic attraction, the collected nanofibers may not be compacted resulting in a more open fiber arrangement. Chvojka et al (2013) used a circular fan blower to push the electrospinning jets from needleless emitter to a collector placed at the side of the emitter. They have shown that this technique is able to construct a thick and fluffy nanofibrous structure. As the electrospinning jets were being diverted, carbon particles were dispersed onto them to create a composite structure. The carbon particles may facilitate in the neutralization or reduction of the charges on the electrospinning jets and this will reduce fiber compaction on the side collector due to charges on the jets. Domjan et al (2020) used a rotating spinneret for electrospinning of water soluble 2-hydroxypropyl-β-cyclodextrin (HP-β-CD) fibers. Instead of using a conventional solid collector, produced fibers were collected in a cyclone. This cyclone creates a swirling wind that keeps the fibers moving instead of adhering to a surface. As more fiber gathers, a porous bulk structure is formed. An advantage of the cyclone is that it is already used at an industrial level for other purposes and may be adapted for collection of electrospun fibers.

High-speed electrospinning (HSES) device equipped with continuous cyclone sample collector [Domján et al 2020]. |

Similarly, using a deionizer to blow ions on an electrospinning jet may also facilitate in the production of three-dimensional (3D) scaffold. However, neutralization of the charges on the electrospinning jet should only take place after the electrospinning jet has been sufficiently stretched and dried such that beads will not form when the charges are removed. Thus placement of the deionizer further from the emitter is recommended.

Last updated: 27 July 2021

ElectrospinTech

ElectrospinTech