Accelerated Electrospinning Jet Solidification for constructing thick scaffolds

As the solvent evaporates from the electrospinning jet as it travels from the solution dispenser to the collector, it will gradually solidifies and stiffens. During deposition, the fibers will bend as it lies on top of one another given their high aspect ratio and flexibility due to the presence of residual solvents within. However, if the jet solidification can be accelerated, the fiber will have a greater stiffness and this may give it a greater resistance to bending which makes it less likely to be compacted.

|

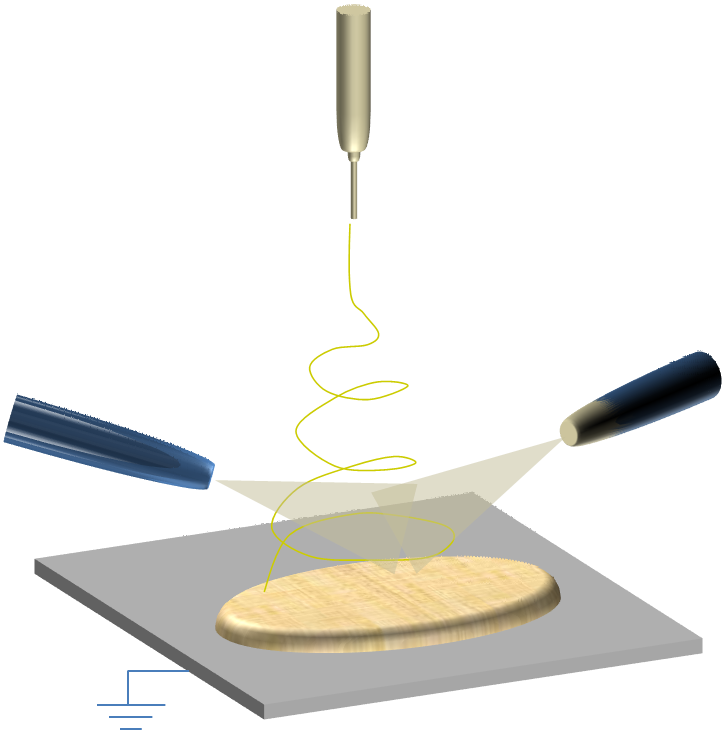

| Schematic illustration of focusing light to accelerate electrospinning jet solidification before deposition on collector. |

Increased stiffness before the fibers are deposited will result in less compaction and greater volume especially for polymers with higher intrinsic stiffness. Shabani et al (2012) successfully demonstrated this effect using poly(L-lactic acid) (PLLA). To increase the solvent vaporization of the electrospinning jet, an array of halogen lights were focused on the electrospinning jet as it nears the collector. This effectively solidifies the electrospinning jet just before it deposits on the collector and giving it the stiffness to resist bending and compaction. A comparison was made with the same parameters except without the halogen lamp and the result shows that it is much more compact with conventional electrospinning setup.

There is a key difference between this concept and uniform heating of the electrospinning chamber to increase solvent vaporization. For this concept, the electrospinning jet is allowed to stretch for most part of its flight and rapid solidification only takes place close to the point of deposition. Uniform heating of the chamber will increase solvent vaporization but it may result in clogging of the nozzle tip or thick fibers due to premature solidification.

This concept may not be restricted to the use of heat to encourage solidification of the electrospinning jet. Light reactive polymers may also be used to initiate polymerization using suitable light wavelength based on the same concept. It will also be interesting to find out whether this concept can be used to control the porosity of the resultant scaffold based on the extent of solidification.Last updated: -

ElectrospinTech

ElectrospinTech